Industry 6.0 Is Coming

- By Varun Rambal & Todd Wandtke

- Read Time: 4 Min

In the long history of industrial evolution, few moments mark a sharp departure from the past, forcing even the most entrenched enterprises to reconsider their foundations. We are now at one of those moments.

Industry 6.0, a phrase that may sound speculative to some, is already here in prototype form. It is not a refinement of current methods. It is a wholesale redefinition of how we conceive, design, and build the physical world.

Imagine describing a product idea in natural language — whether that’s a mechanism, a consumer good, or a component — and receiving the final product fully assembled in hours. All of it being done with no designers, no production planners, and no assembly line workers involved. Such an opportunity results from recent breakthroughs in generative AI and swarm robotics that eliminate the need for human input across the entire manufacturing chain.

From Co-Pilot to Full Autopilot

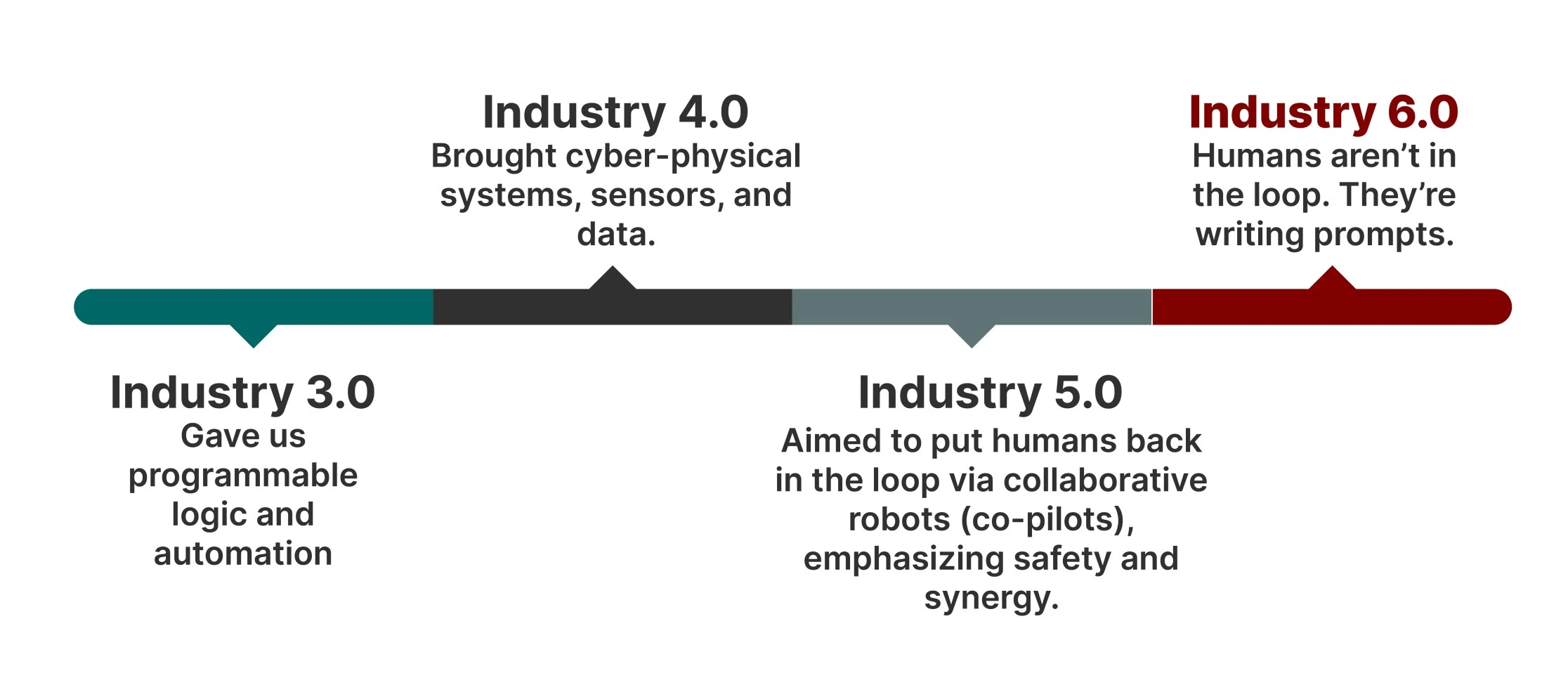

To understand the significance of Industry 6.0, let’s briefly revisit where we’ve been:

Industry 4.0 introduced cyber-physical systems and real-time data analytics, Industry 5.0 added human-machine collaboration, and Industry 6.0 moves beyond both. It proposes a world in which large language models (LLMs) govern heterogeneous fleets of robots, including manipulator arms, drones, 3D printers, and mobile units, orchestrating a fully autonomous “prompt-to-product” pipeline.

It is a strategic transformation that challenges the traditional levers of industrial leadership, be it scale, labor efficiency, and supply chain dominance, and replaces them with a new currency in adaptive intelligence and architectural control.

A New Industrial Brain

At the center of Industry 6.0 is a distributed AI system, which includes a heterogeneous swarm of robots such as 3D printers, drones, and robotic arms, capable of reasoning across domains, interpreting objectives, and directing action with little human assistance. A prototype developed by researchers at Skoltech using OpenAI’s GPT-4, LangChain, LangGraph, and locally deployed LLMs, enabled one such distributed AI system to generate 3D blueprints autonomously, convert them into print-ready files, coordinate drone-based logistics, and execute robotic assembly. The results were striking: average production time reduced by 77 percent; blueprint generation cut from nearly 24 minutes to just 30 seconds; assembly instructions inferred from simple prompts.

In this new model, the factory itself becomes a semantic environment, a space where intentions are translated directly into execution via knowledge-informed reasoning. The architectural parallel here is unmistakable to those already thinking beyond automation and into the terrain of cognitive infrastructure.

It mirrors what we at Mu Sigma have called ‘semantic guardrails’, a framework that provides a contextual blueprint for Agentic AI through ontologies, knowledge graphs, and question networks. Backed by years of organizational data and knowledge, this context can be interpreted and used by networks of intelligent agents and optimized continuously by feedback loops embedded within the system.

Industry 6.0 is the semantic guardrails applied to manufacturing.

What This Means for Industrial Strategy

If you’re a Fortune 500 manufacturing executive, Industry 6.0 demands attention not because it’s shiny or new, but because it fundamentally alters the logic of value creation. What once took armies of skilled designers and years of plant optimization now collapses into a cognitive loop between intent and artifact.

The implications are profound. Production costs no longer scale with headcount, product personalization no longer incurs design overhead, and downtime becomes an optimization problem solved by the system itself.

But most importantly, speed becomes strategy. Speed to design. Speed to iterate. Speed to deploy. Speed to pivot entire product lines in response to customer need, market fluctuation, or geopolitical risk. It is a native property of an AI-first production architecture.

The Risk of Linear Thinking

Still, many companies will misread this moment. They will mistake it for a sophisticated extension of current automation efforts. They will see it as another technology to deploy, not as new grammar for how things are made.

The systems behind Industry 6.0 can learn, adapt, and optimize across product cycles. They are systems of exploration guided and constrained by semantic guardrails, including ontologies, knowledge graphs, and question networks.

With Industry 6.0, organizations that can ask better questions, refine their objectives, and evolve in pursuit of their goals are the ones that will have thriving AI systems that are agile and adapt to organizational needs.

The Time to Move Is Now

No one is suggesting you replace your factories tomorrow. But neither can this shift be deferred indefinitely. The early signals are here, and they are loud.

This is the moment to build capability. To prototype a closed-loop production cell. To codify your design language into machine-readable prompts. To capture knowledge as graph, not just process.

Organizations who lead this charge will offer personalized products at scale with minimal cost trade-offs. They will run lighter, faster, and more resilient operations. They will convert factories into platforms, and platforms into profit centers. They will stop reacting to market shifts and start predicting them.

In the end, the revolution of Industry 6.0 blurs the line between design and execution, between intent and artifact, between CEO and prompt engineer. It is the manifestation of systems that explore, adapt, and compose. Systems that transform not just what we make, but how we think about making.

The question is no longer How fast can we build? It is How fast can we think?