Supply Chain Optimization

A top medical device manufacturer faced forecasting challenges due to the unforeseen impact of COVID-19. Mu Sigma responded to this challenge with a self-serve simulation tool, improving accuracy and mitigating pandemic-related risks.

Since March 2020, the medical devices manufacturer’s business processes for forecasting demand across multiple product lines experienced significant setbacks. These processes were not originally designed to anticipate the impact of COVID-19.

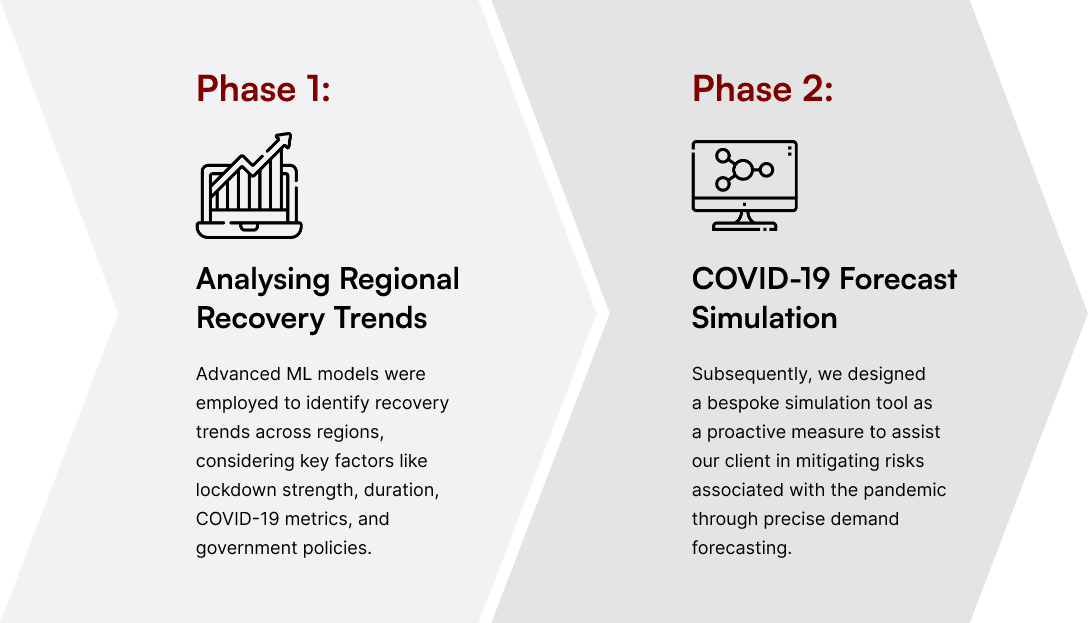

Mu Sigma devised a two-phased solution to ensure a resilient supply chain through the COVID lockdown and recovery.

We leveraged a precise blend of statistical modeling, machine learning, and strategic business insights to build this scalable, self-service tool. In addition to obtaining data, implementing a quality control framework, and preparing data for modeling, adjustable COVID-19-related features were included to serve as inputs for the forecasting model. Furthermore, a data warehouse was established to house pertinent data for the visualization layer, enhancing the overall analytical capabilities of the system.

We also built a web application to empower users to customize features, visualize impacts, access reports, and download forecasts. This facilitated seamless integration of forecasts into other systems, enhancing the overall utility of the solution.

The implemented solution addressed the immediate need for accurate demand forecasting and provided the client with a robust framework for supply chain planning in the face of shock events such as the COVID-19 pandemic.

-

40%

Improvement in Demand Forecasting Accuracy

-

Boosted Agility

Across the supply chain to enable antifragility

Mu Sigma is the world's largest pure-play big data analytics and decision sciences company. Through our Art of Problem-Solving, we strive to scale and systematize better decision-making through business intelligence services. Mu Sigma works across the entire decision support ecosystem (data sciences, data engineering, and decision sciences) with Fortune 1000 companies worldwide, including 140+ Fortune 500 companies.

The firm's is derived from the statistical terms "Mu" and "Sigma," which symbolize a

probability distribution's mean and standard deviation, respectively.